Shock and Temperature Monitor and Logger

Shock and Temperature Monitor and Logger

IMMEDIATELY Finds Sources of Damage to Fresh Produce

The ImpacTrack shock sensor and logger monitors damage to fresh produce caused by handling and transport operations. It can help to reduce food production waste, monitor transport and logistics and improve quality control systems.

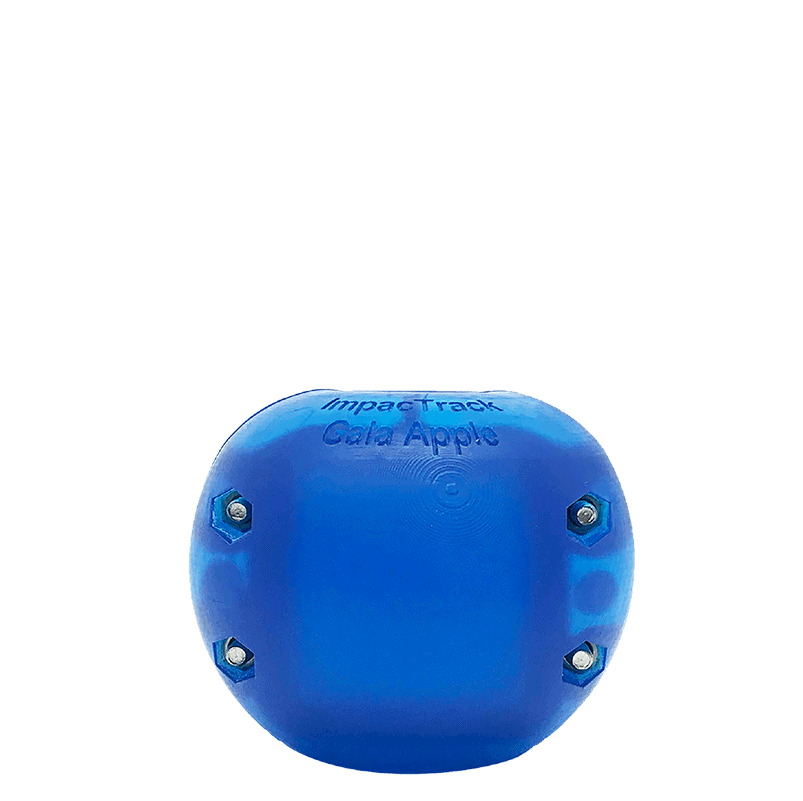

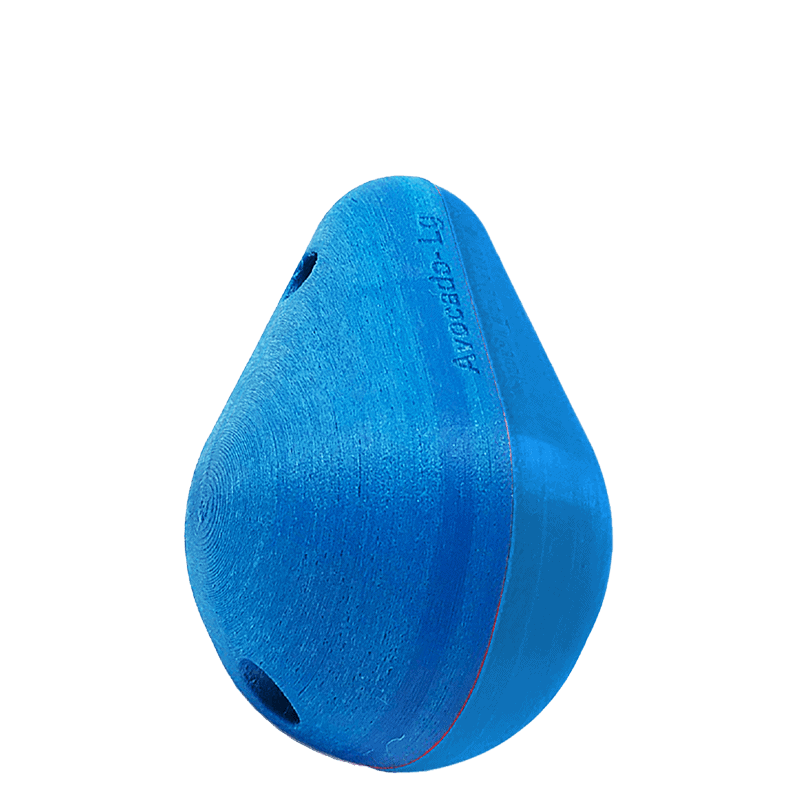

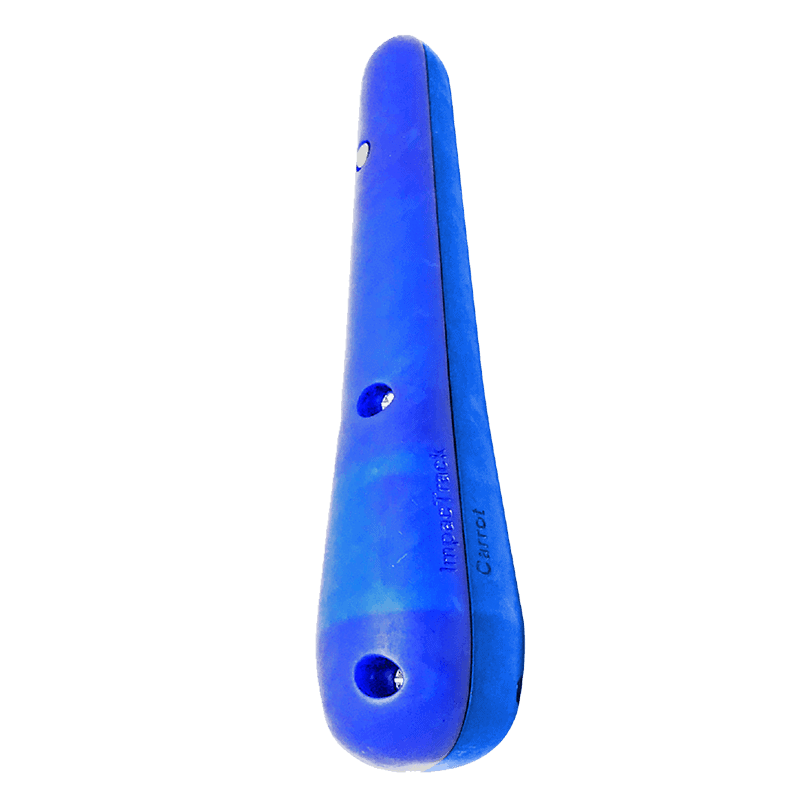

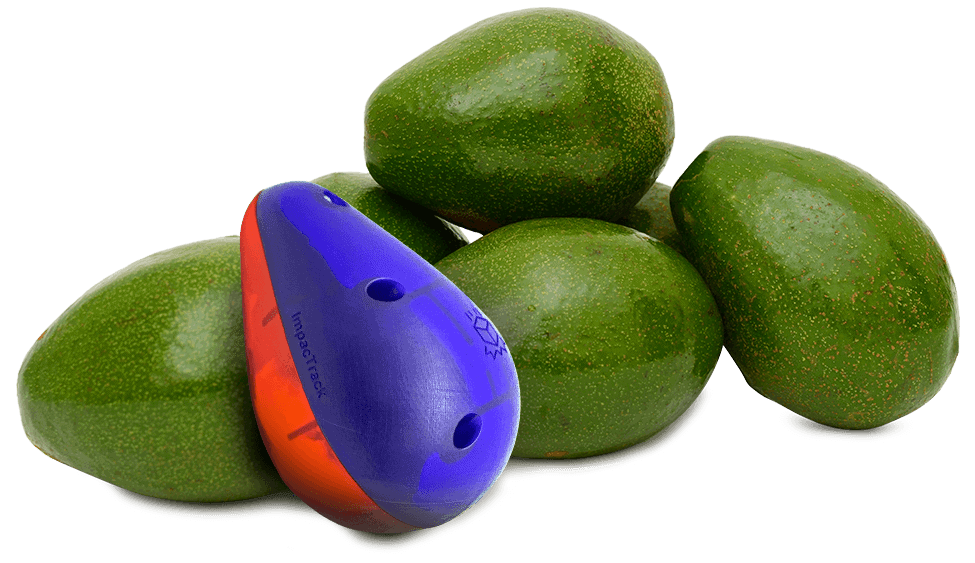

The ImpacTrack logger is encased in a shell which mimics the dimensions, shape, weight and density of the real produce. It will behave and react (including floating in water) in the same way as the produce you are working with.

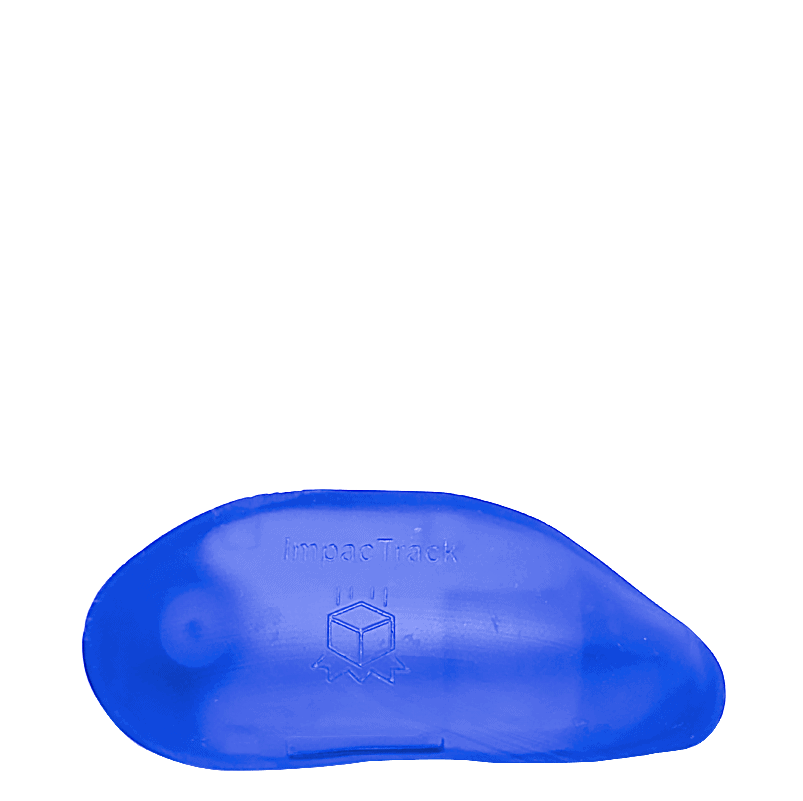

The ImpacTrack logger can also be used on its own to monitor transport operations. It is small enough (a 3cm cube) to be located discretely inside packing containers. Using the smartphone App, the logger can be set to begin recording at the start of a transport event and, when retrieved at the destination, the data can be downloaded to another smartphone.

Key Features

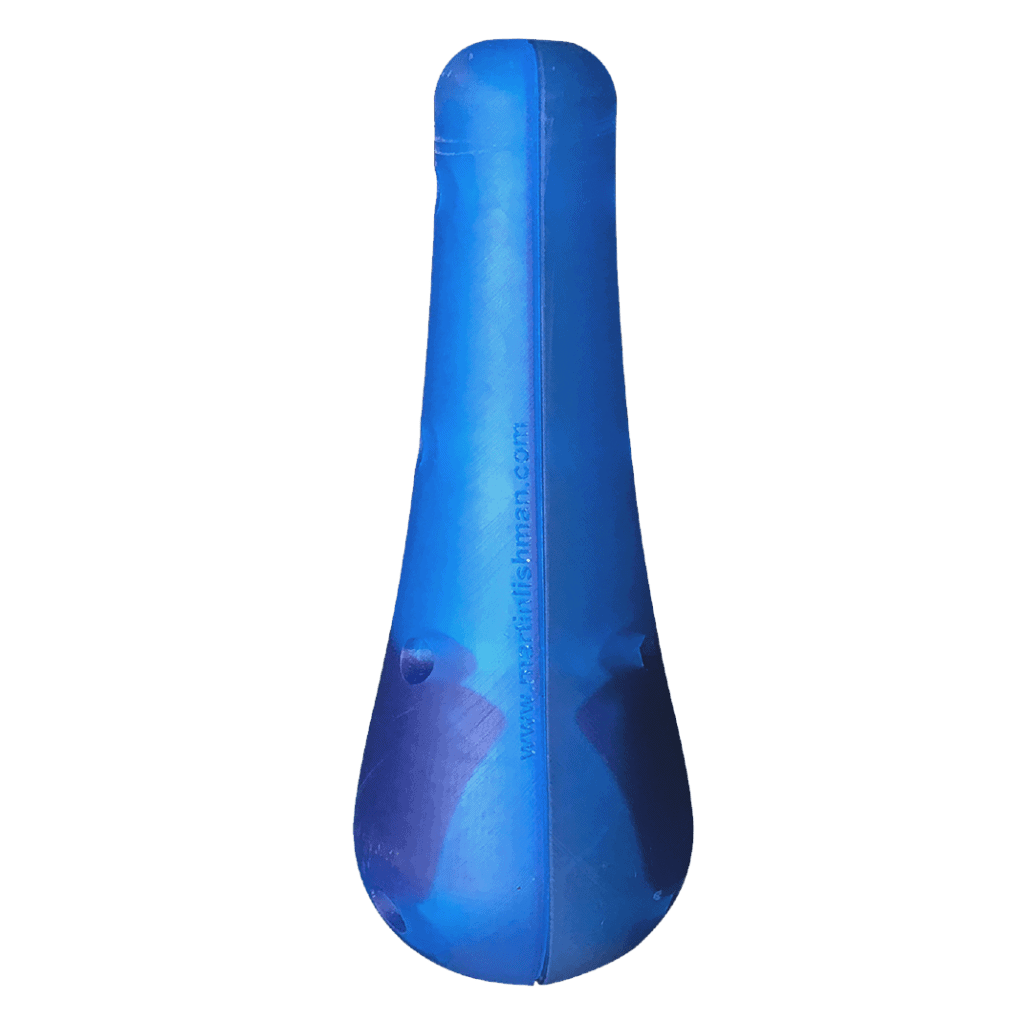

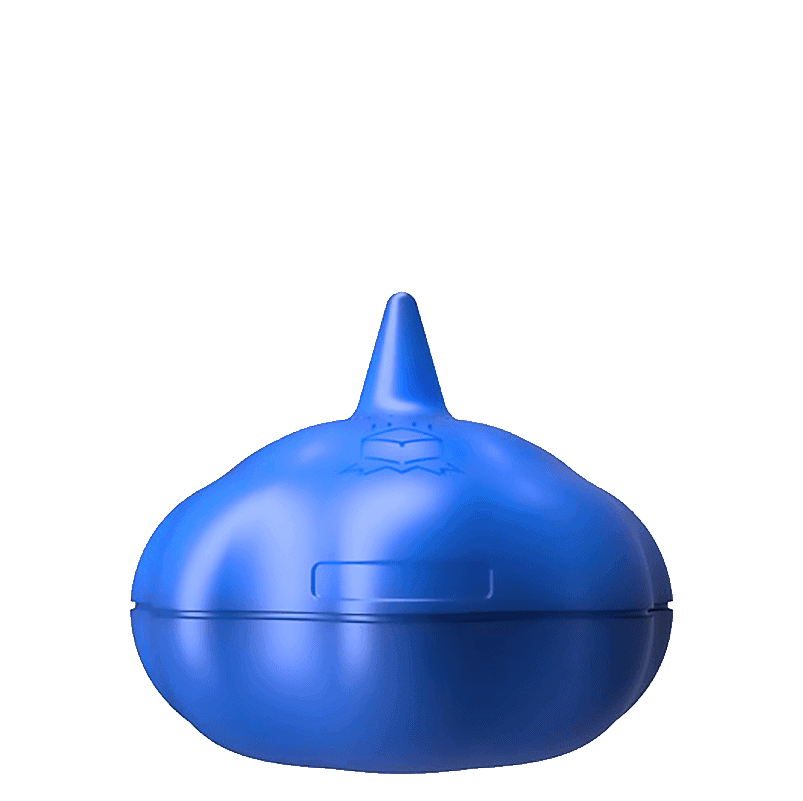

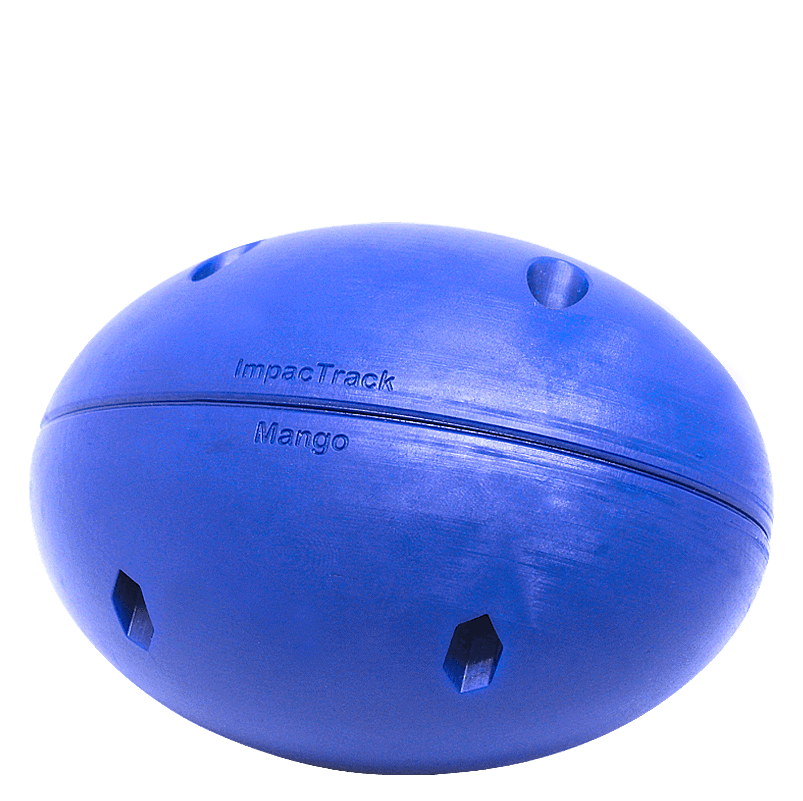

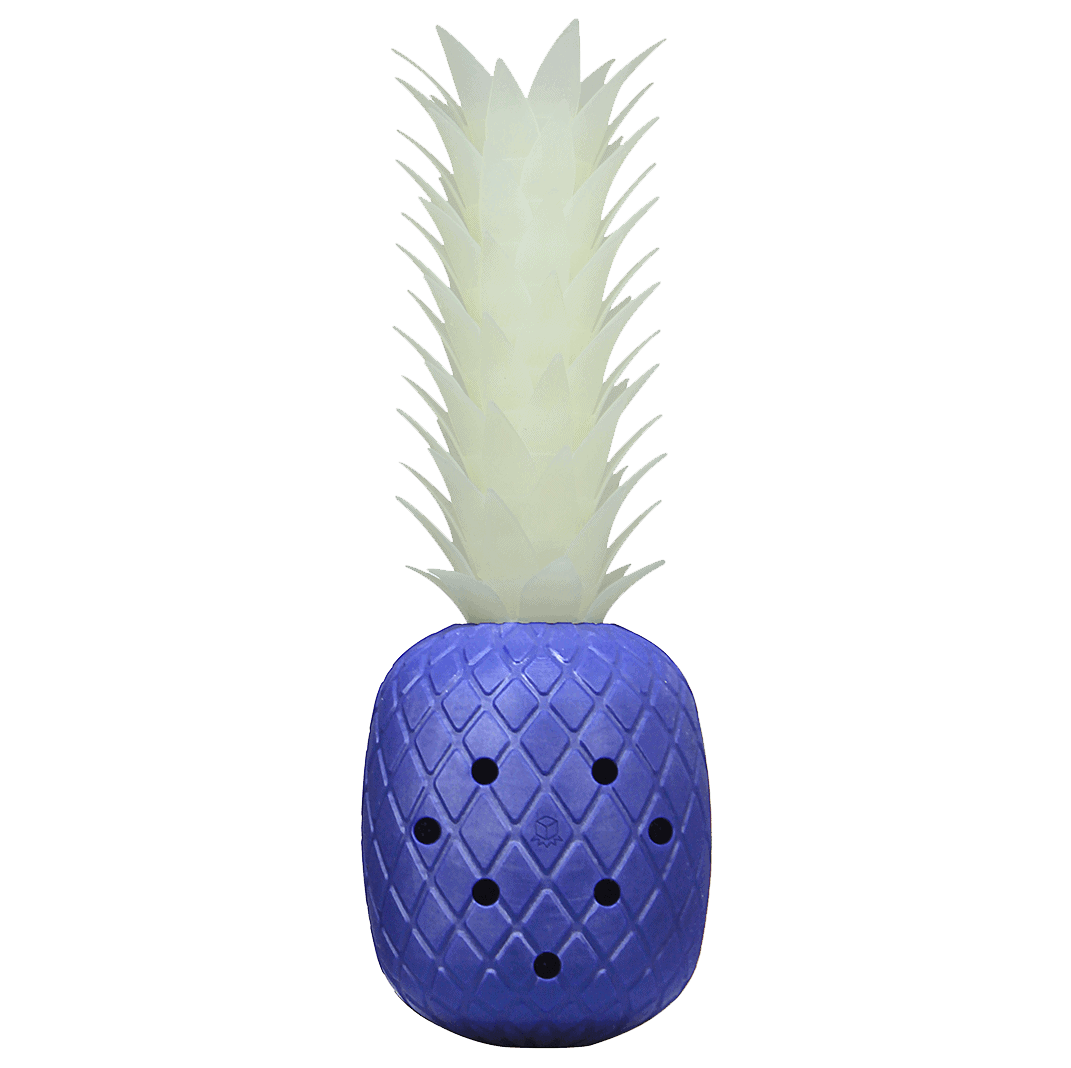

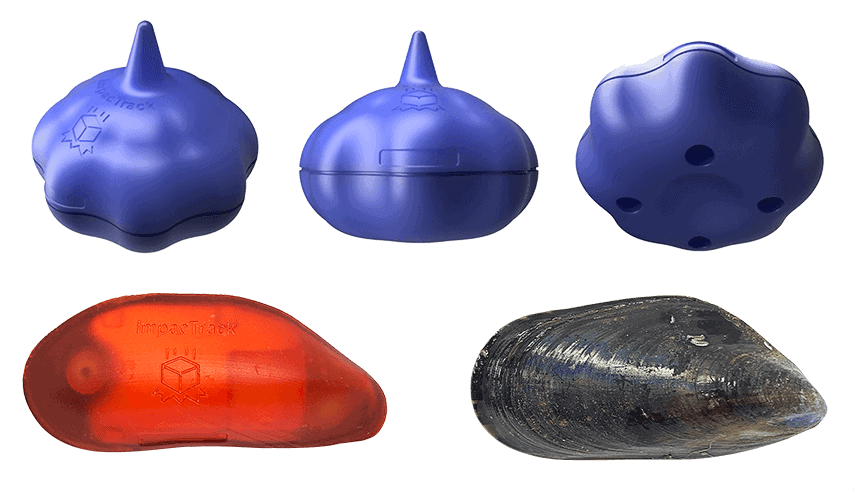

Carrier shells available to match the shape, size and density of the real produce being monitored:

Don’t see the shape you need? No problem, simply contact us with your requirements and we can make it for you!

“Following the results of the ImpacTrack tests we were able to implement modifications to the grading and packing equipment which has reduced the g-force impact to the fruit. I believe it is an excellent device to be used in post-harvest handling.” Read More

Greenyard Fresh UK’s

Technical Manager

“An easy to operate device providing instant results to which remedial action can be carried out.” Read More

University of Lincoln, UK

“The electronic apple allowed us to pinpoint where the maximum force was. Armed with that knowledge, we were able to redesign the system to reduce that force below the damage threshold. This is a major benefit to fresh produce packers, for whom waste as a result of bruising is a considerable – and largely avoidable – cost”. Read More

Brillopak’s Technical Director

“ImpacTrack helps us to accurately measure the different avocado handling steps. The impact sensors let us see exactly where the stress points are. The temperature values are also very useful as the avocados are sensitive to temperature changes.” Read More

The Cube

At the heart of the ImpacTrack is a 3cm data logger cube that houses a 3 axis shock sensor, temperature sensor, bluetooth transmitter, data memory and battery.

The Shape

Designed to meet your specific requirements, we can match the size, shape and density of real produce in order to reproduce the movement characteristics of fruit and vegetables prone to damage and bruising during handling and transport and therefore get as close as possible to a realistic representation of impact ‘black spots’ in handling machinery.

8 different apple shapes with many different weights have been created, to reflect different varieties and densities – allowing the shape to float at the same level as the real fruit

Complex shapes such as garlic or mussel can be created, and can be waterproof if required, to suit the handling and processing systems

The recommended weight range reflects typical weights of real produce with the dimensions listed. When choosing a shape, it is important to know the average weight of the produce with the same average dimensions. The final weight of the ImpacTrack is then matched to this so that it behaves and reacts (including floating in water) in the same way as the real produce. Most shapes are waterproof and can have the same buoyancy as the produce being processed.

Contact us now to discuss your requirements.

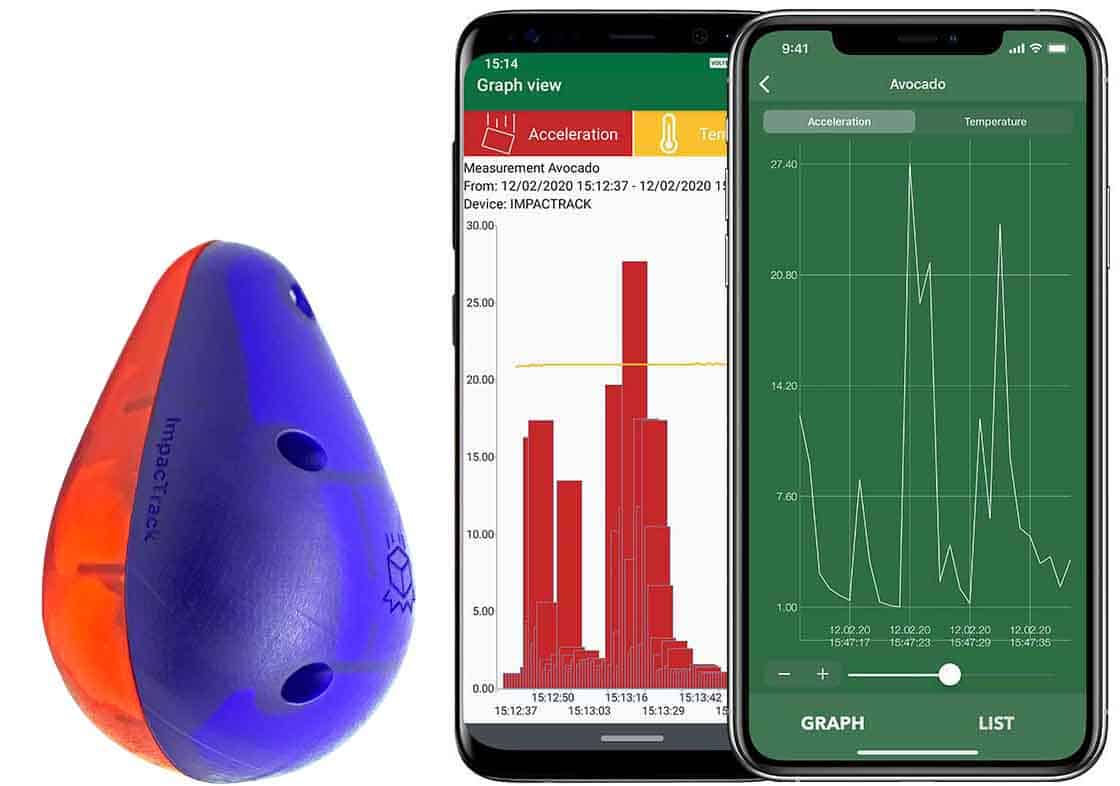

ML Sensing App

The multi-lingual iOS and Android ML Sensing app connects to the ImpacTrack via Bluetooth and can be used to view the logger in real time, or to set the logger to record internally for extended shipments. The data gathered can be downloaded at the end of the journey into the App and can be viewed in table or list view. The data can also be exported via email in a .csv format for further data analysis.

*iOS and Android app appearance may differ depending on device

Built to last

All our ImpacTrack shapes are designed to withstand the conditions real produce faces as it passes through the various stages of handling machinery. Shapes can be waterproofed to suit water-handling and washing areas of machinery. Contact us now to discuss your requirements.

| Product Code | Range | Accuracy | Resolution | Battery | Measuring interval | Start Delay | Memory | Data Transfer | Max Distance | Data format |

|---|---|---|---|---|---|---|---|---|---|---|

| CQ/IMPACTRACK | -25°C to +75°C Up to 27g (G-Force) | ±0.5°C ±0.25g | 0.1°C 0.1g | Lithium 1/2AA 3.6v Approx. 6 month battery life | 1s - 24hr adjustable | 1s - 6 month adjustable | Max. 32,000 values | Bluetooth 4.0 | 40m Line of sight | CSV export |

Damage and bruise testing in other produce with ImpacTrack and TuberLog

Known worldwide as the “Electronic Potato” the TuberLog has been designed specifically for testing potato harvesters and handling equipment.

The BeetLog takes its design cues from the TuberLog, but re-engineered to mimic the size, shape and density of a sugar beet.

© Copyright 2024 Martin Lishman Ltd. All rights reserved.

Keep up to date about future news, events and products from Martin Lishman.