Immediately identifies sources of damage and bruising

The BeetLog Electronic Sugar beet identifies damage and bruise causes in all types of sugar beet handling machinery.

The operator watches the BeetLog passing through a machine and its Bluetooth technology links to an Android app to help immediately indicate sources of impact.

BeetLog enables immediate improvements to quality problems in sugar beet production.

BeetLog assists with the prevention of economic losses caused by bruising.

How does BeetLog work?

Android App

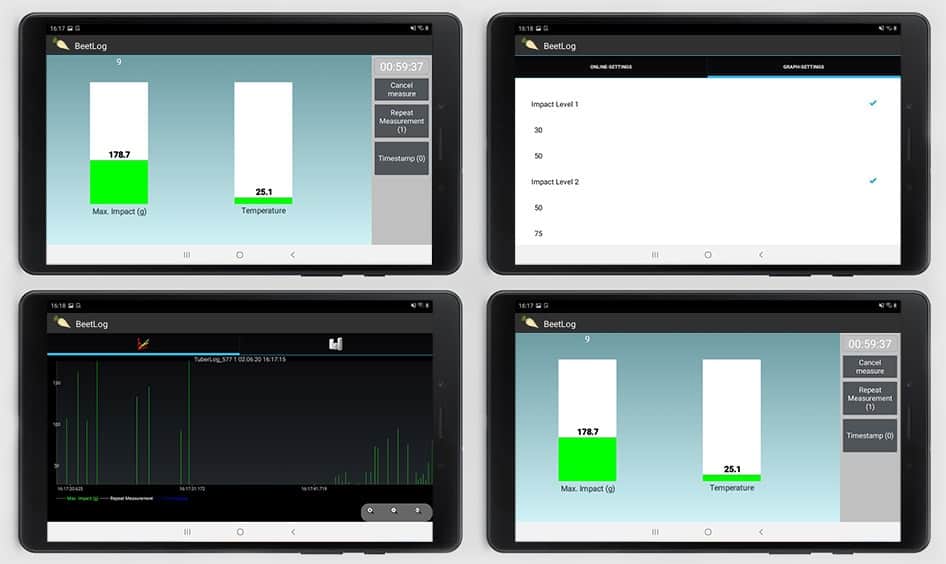

The BeetLog connects to an Android tablet via Bluetooth. The app gives users the ability to see in real time the shocks received by the BeetLog. Operators can accurately identify the location and severity of the shock and quickly decide whether remedial work is needed.

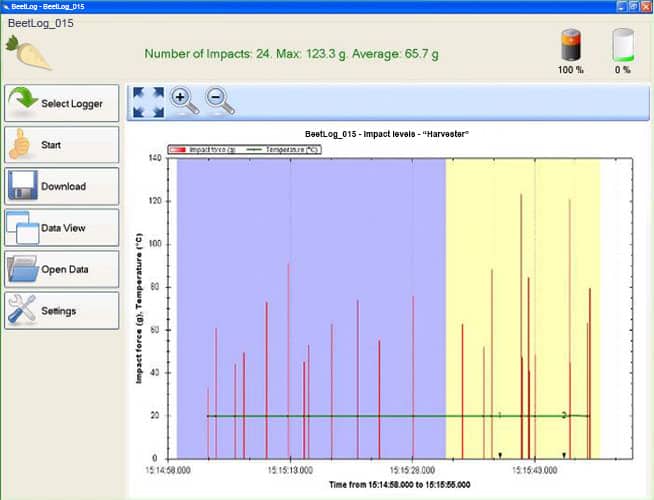

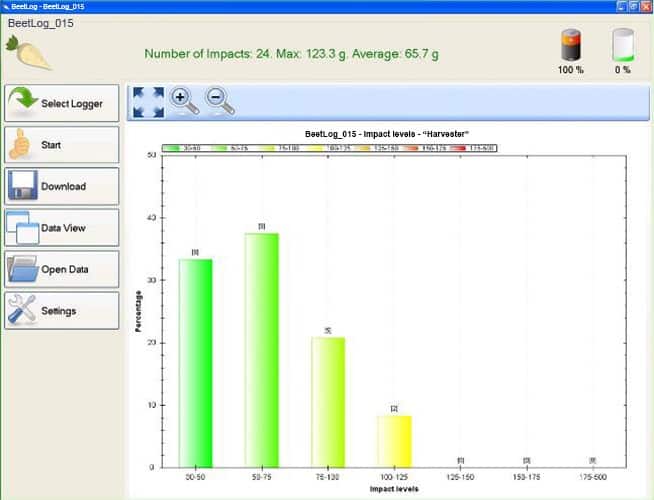

Operators can select their own reporting thresholds, so small shocks show up as a green alert, intermediate ones as orange and severe ones as red. Each alert is accompanied by a different audible alarm.

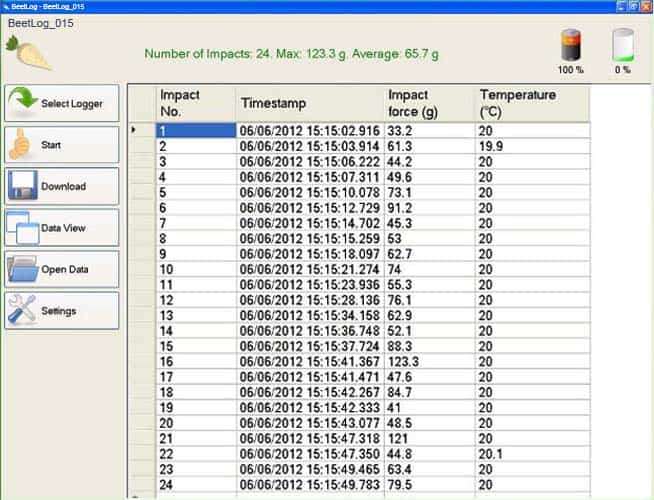

The recorded data can be viewed in real time and can be viewed in different forms such as tables or graphs.

Suited to testing all sugar beet harvesting and handling situations

Interpretation of Results

Sugar beet damage is related to impact, but variety, temperature and growing conditions all affect how much bruising occurs at a given impact.

BeetLog doesn’t measure damage levels in real sugar beet, but the user can interpret the impact information and change machine settings to reduce impact levels and minimise damage.

PC software allows detailed analysis of impact records

Why use BeetLog as part of quality control procedures?

BeetLog assists with the prevention of economic losses caused by bruising

BeetLog enables immediate improvements to quality problems in sugar beet production

BeetLog can provide peace of mind that quality standards are being maintained

BeetLog should be used regularly so that bruising problems caused by poor machine maintenance or incorrect settings can be detected quickly. Machine settings are often changed, but the effects on bruising may not be realised. A quick check with BeetLog can make sure.

Who can benefit from using BeetLog?

Sugar beet growers, producers and processors

Manufacturers of harvesting and post-harvesting machinery

Agronomists and Crop Consultants

Research and development technicians

2 Versions available

BeetLog PTR600

Sugar beet shape datalogger, App, PC software

BeetLog PTR700

Sugar beet shape datalogger, App, PC software, Android tablet

| Sampling rate | Weight | Dimensions | Power | Bluetooth operating range | Case dimensions | Weight full |

|---|---|---|---|---|---|---|

| 1000 Hz | 1.9kg | 23 x 14 x 5cm | Rechargeable battery Life: 10hrs to 1 month Depending on use | 20m Line of sight | 30 x 28 x 16cm | 2.9Kg |

PTR 600 (Product Code: POT/PTR600)

Data logger embedded in a synthetic shape designed to mimic the size, shape and density of a sugar beet, with replaceable sealing caps

QR code link to download:

– BeetLog App suited to Android tablet or smartphone (not iOS)

– PC software for unlimited data download function

– Instruction manual in English

Bluetooth USB adapter; USB connection and charging cable; strong carry case

PTR 700 (Product Code: POT/PTR700)

As PTR 600 above, with Android Tablet, pre-loaded with BeetLog App

Operating method: 3-axis shock sensor with sampling rate of 1000 Hz, selectable measurement period and pre-set peak value threshold. Data readout is wireless via Bluetooth interface or USB connection to a PC (using software supplied) or Android tablet or smartphone (using App supplied or downloadable from the Google Play Store).

Tablet specifications may vary according to available model and manufacturer

Damage and bruise testing in other produce with ImpacTrack and TuberLog

Any size, any shape.. See how ImpacTrack can help reduce bruising in almost any produce!

Known worldwide as the “Electronic Potato” the TuberLog has been designed specifically for testing potato harvesters and handling equipment.

© Copyright 2024 Martin Lishman Ltd. All rights reserved.

Keep up to date about future news, events and products from Martin Lishman.