Automation has taken over the packhouse, but can we trust these machines to maintain the quality control of their human counterparts? UK-based Brillopak, leading innovators in fully automated fruit picking and packing lines, have turned to an “electronic apple” to demonstrate that its systems do not damage the fruit and can help to reduce customer wastage costs and improve line efficiency.

Martin Lishman’s ImpacTrack, an award-winning shock sensor encased in a shape that mimics real produce, was used to help Brillopak test its automation systems. Designed to reveal areas of potential damage throughout processing lines, linking the ImpacTrack to a smartphone or tablet via Bluetooth allows the data to be viewed in real time to show potential sources of damage in handling machinery.

Brillopak used Martin Lishman’s ImpacTrack apple shape to test their reject system, an advanced automated system that scans a flow-wrapped pack of apples and rejects them if one of the apples does not meet the requirements. It was placed in the pack with other apples to make the test as realistic as possible. They discovered that when apples were pushed off the conveyor belt, some of them were subjected to bruising, making them unsuitable for repacking.

Brillopak were able to design an alternative reject system that guides rejected packs off a belt at a shallow angle using a flexible polyurethane band pusher. This mechanism significantly reduced the impact forces on the apples, allowing many more to be repacked.

“The ImpacTrack allowed us to pinpoint where the maximum force was,” explains Peter Newman, Brillopak’s Technical Director. “Armed with that knowledge, we were able to redesign the system to reduce that force below the damage threshold. This is a major benefit to fresh produce packers, for whom waste as a result of bruising is a considerable and largely avoidable cost.”

Brillopak have gone one step further using ImpacTrack to monitor its pick-and-place systems, a potential hotspot for damage with some robots dropping fruit from heights of 250mm. The company has developed a robot control system that optimises acceleration and deceleration to minimise this risk.

“When lifting a pack of apples, the robot arm accelerates strongly upwards into a curve, then decelerates down into the crate, so the pack is tightly controlled as it reaches the bottom of the crate,” Newman says. “What sets us apart is our ability to perform this task at high speed without bruising the product.”

By testing their machines with ImpacTrack, Brillopak are able to prove that its automated systems handle the fruit carefully and have been optimised to reduce the impacts as much as possible.

“The use of ImpacTrack to help test automated packing lines such as this is a big step forward for us.” says Gavin Lishman, Managing Director of Martin Lishman Ltd. “Continuous research and development is key to making the food industry more efficient and sustainable. Agri-Tech solutions such as this help maximise the efficiency of food production. The information obtained by ImpacTrack offers reassurance to not only Brillopak, but also the end users of their machines”.

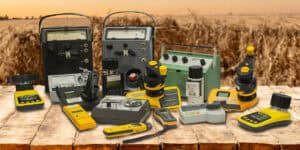

The ImpacTrack shape library is growing rapidly, with Martin Lishman’s ability to design new shapes as per customers’ requests leading so far to more than 20 different types, each with the shape, size, weight and density of the real produce.

Find out more about the ImpacTrack HERE