-

Search

-

Search

- Home

- Products

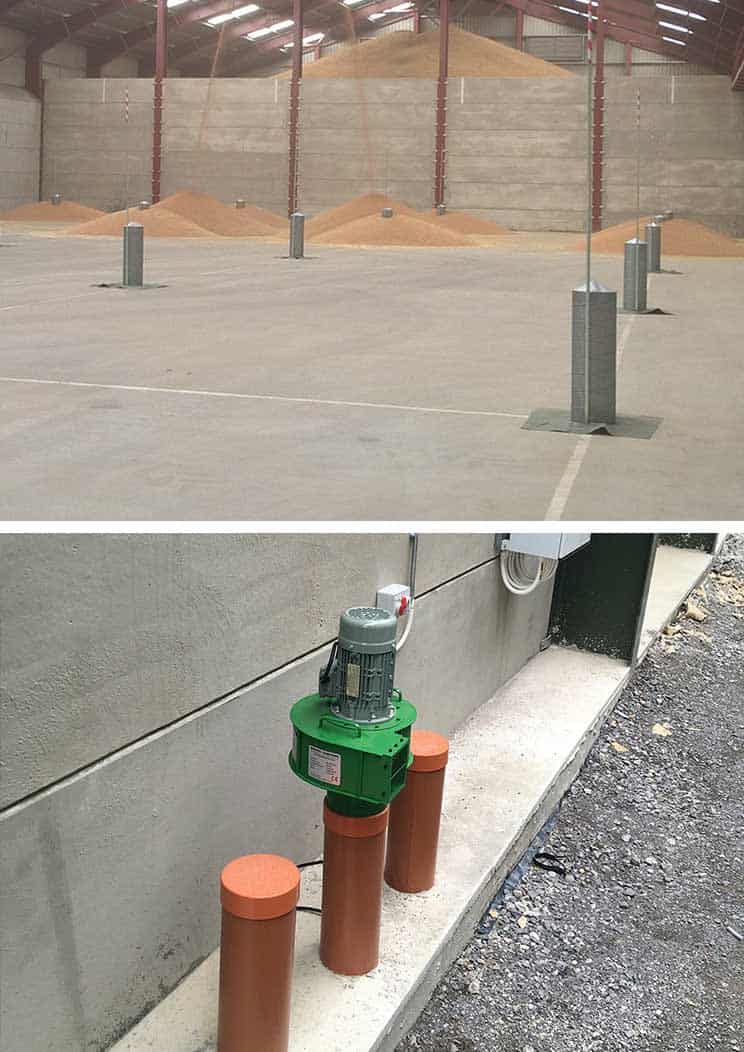

- Grain

- Grain Cooling Systems

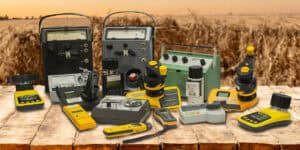

- Crop Quality Equipment

- Moisture Meter Servicing

- Grain Clinics

- Potatoes

- Sprayers

- Soil

- Building Ventilation

- Impact Sensing

- Building Moisture

- Grain

- About

- Learn

- Downloads

- Dealer Locator

- Home

- Products

- Grain

- Grain Cooling Systems

- Crop Quality Equipment

- Moisture Meter Servicing

- Grain Clinics

- Potatoes

- Sprayers

- Soil

- Building Ventilation

- Impact Sensing

- Building Moisture

- Grain

- About

- Learn

- Downloads

- Dealer Locator