PTR 400 (Product Code: POT/PTR400)

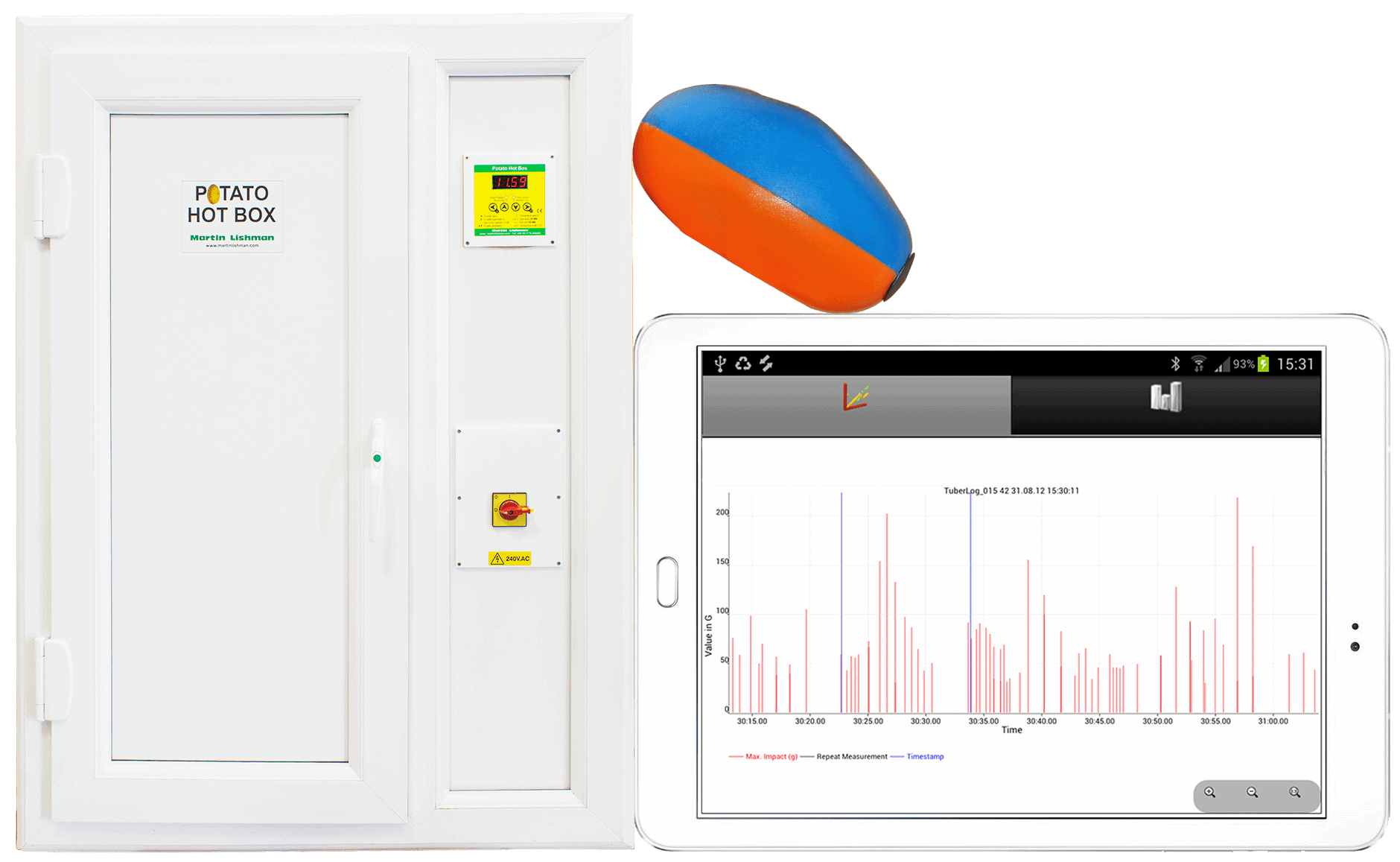

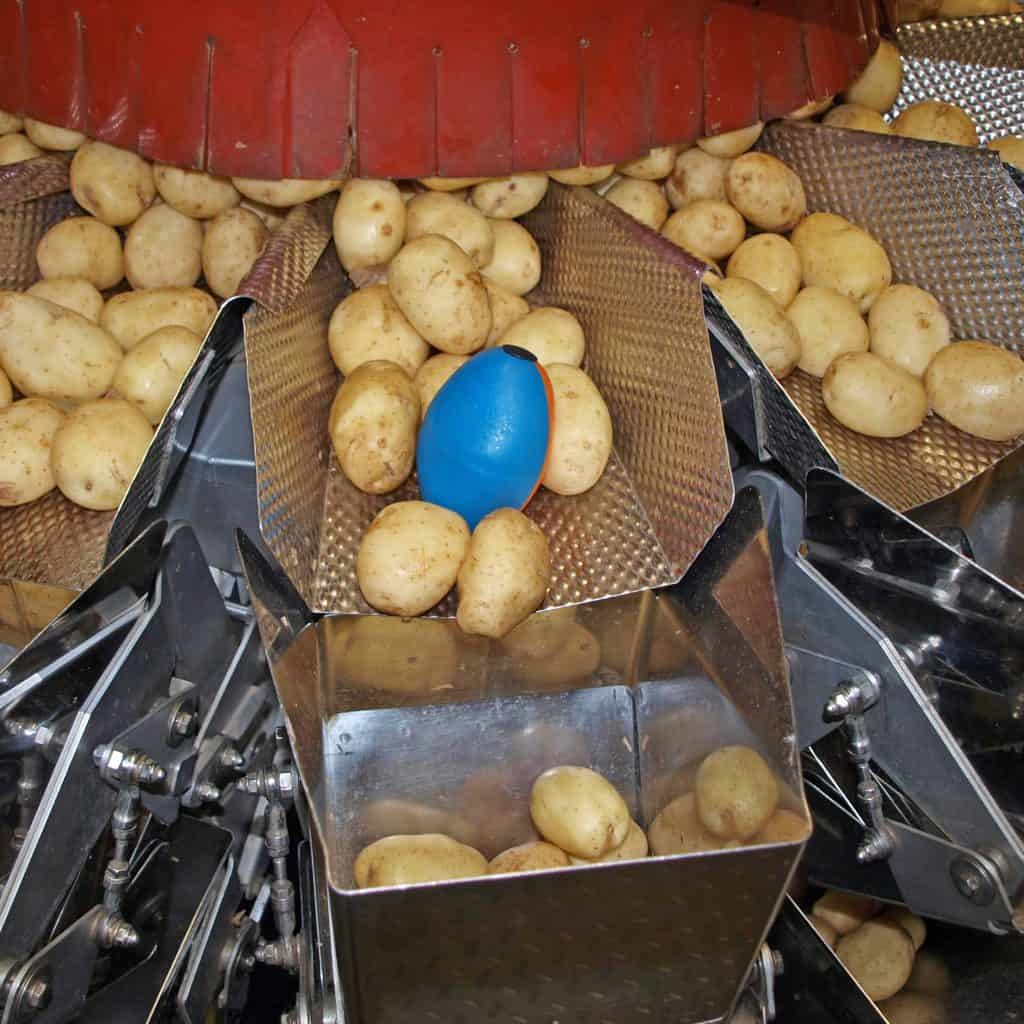

Data logger embedded in a synthetic shape designed to mimic the size, shape and density of a ‘ware’ potato, with replaceable sealing caps

QR Code link to download:

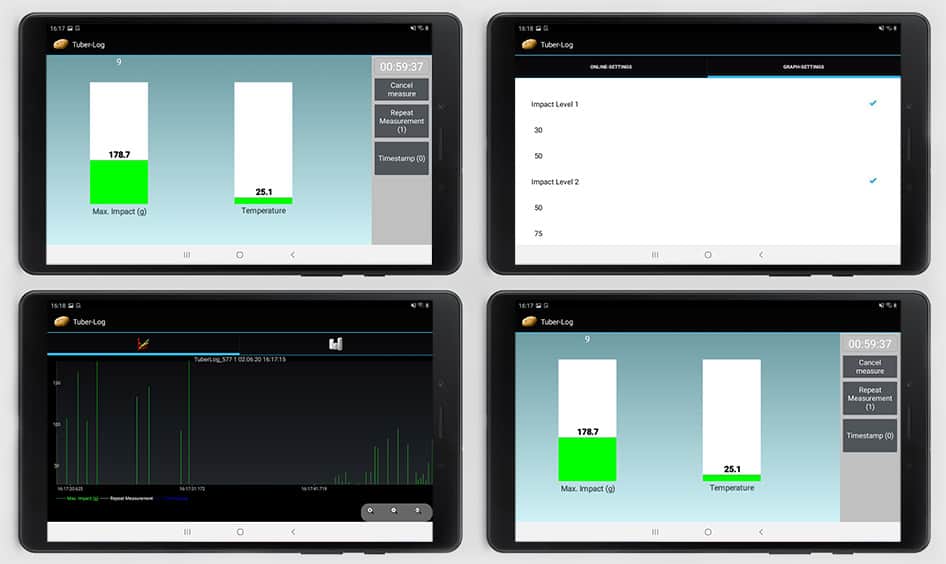

– TuberLog App suited to Android tablet or smartphone (not iOS)

– PC software for unlimited data download function

– Instruction manual in English, French, Spanish and German

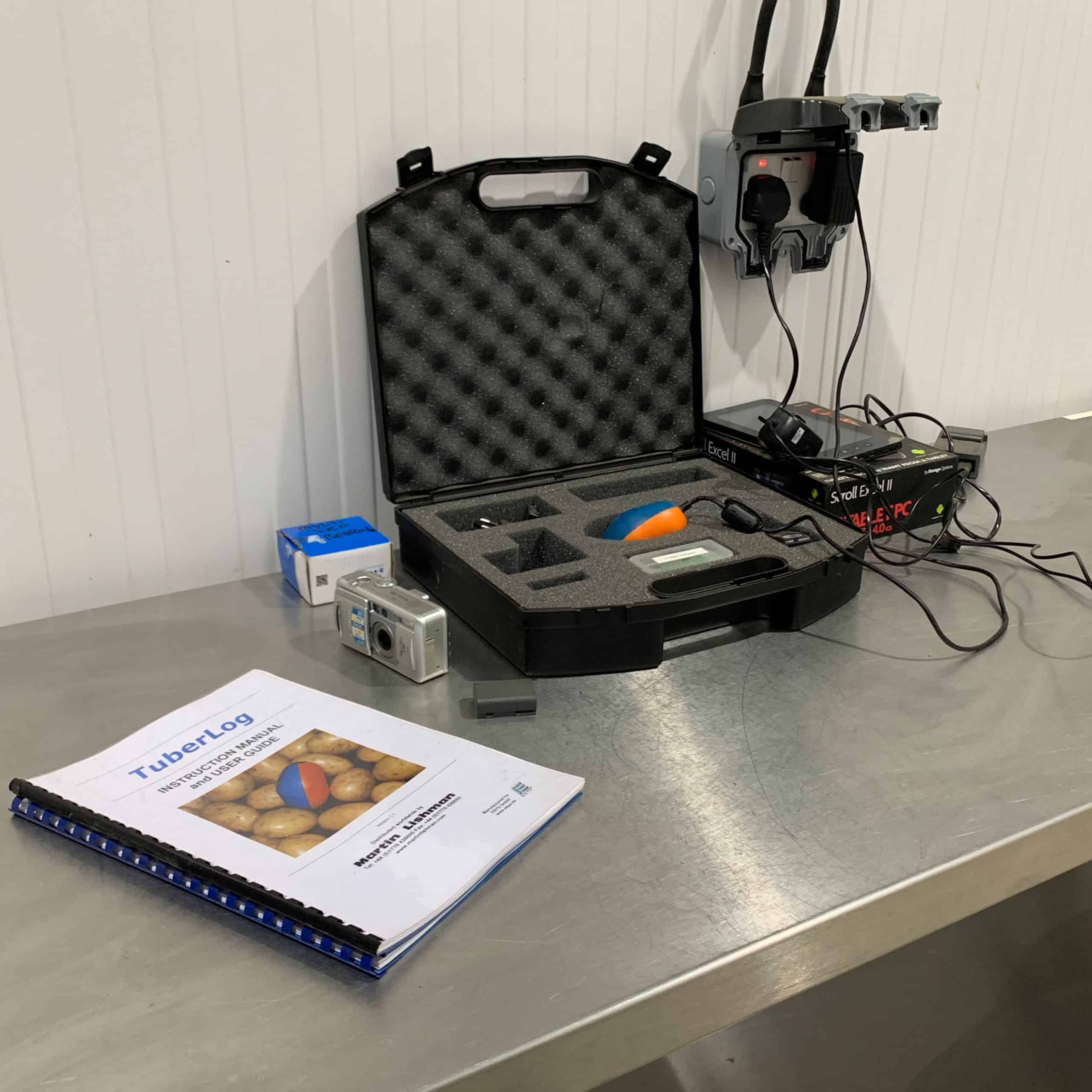

Bluetooth USB adapter; USB connection and charging cable; strong carry case

PTR 500 (Product Code: POT/PTR500)

As PTR 400 above, with Android Tablet, pre-loaded with TuberLog App

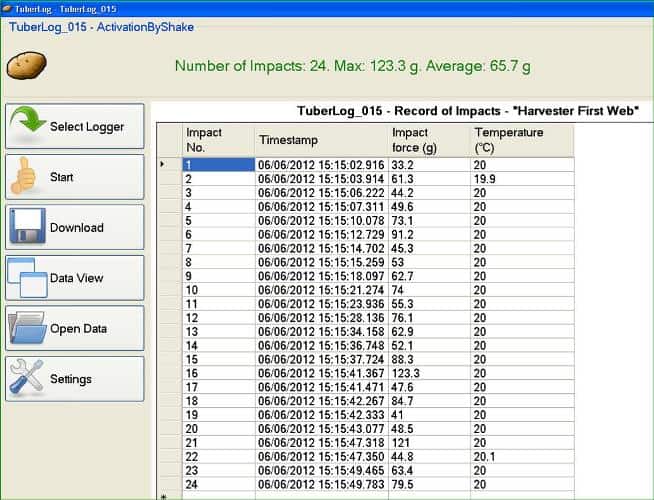

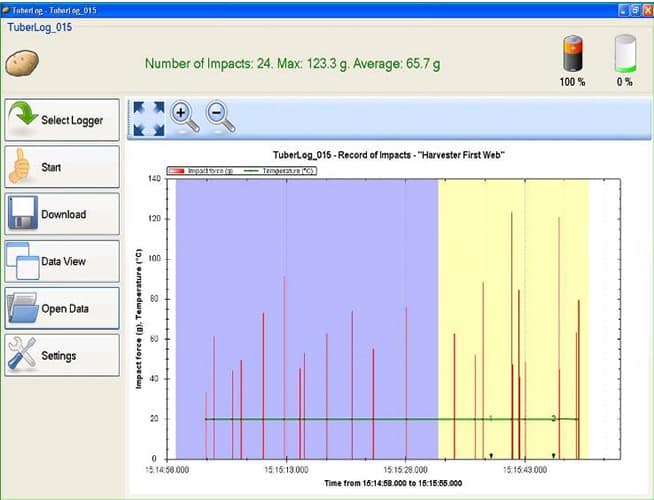

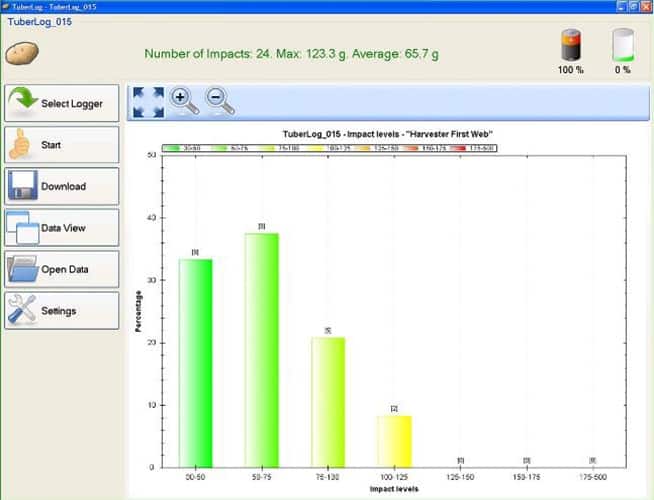

Operating method: 3-axis shock sensor with sampling rate of 1000 Hz, selectable measurement period and pre-set peak value threshold. Data readout is wireless via Bluetooth interface or USB connection to a PC (using software supplied) or Android tablet or smartphone (using App supplied or downloadable from the Google Play Store).

Tablet specifications may vary according to available model and manufacturer