With harvest 2022 looming on the horizon, reports of a barrage of hot weather to sweep across the UK over the next few weeks could mean an early start for some.

With expected hot grain temperatures, ensuring optimal ventilation of the stored crop with a powerful airflow will help drive temperatures down as fast as possible. A suitable automatic fan control system is equally as important in taking advantage of the rare occurrences during the summer months of low ambient temperatures to cool grain and will significantly reduce the energy needed to do so.

Crop storage specialists Martin Lishman Ltd have reported their customers are already gearing up ready for an early harvest this year and opting to increase the cooling power in their stores.

With nearly 50 years’ experience in grain storage technology, Martin Lishman Ltd have developed a wide range of grain quality and crop storage products with thousands of satisfied users worldwide. Driven by demands from the industry, the Martin Lishman line-up supports farmers in their on-going battle to preserve the highest grain quality whilst also reducing energy costs. The company’s industry-leading innovations include the award-winning Barn Owl Wireless automatic fan control and crop monitoring system and the UK’s number one crop cooling system Pile-Dry Pedestals and Fans.

Unrivalled Ventilation

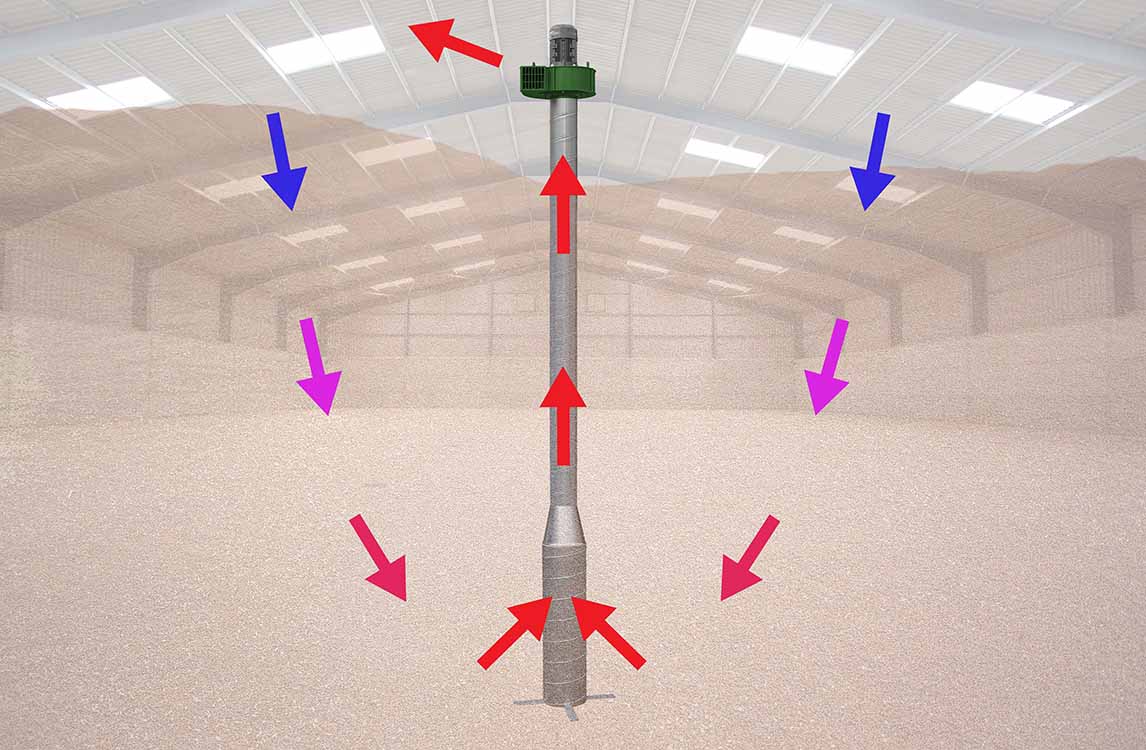

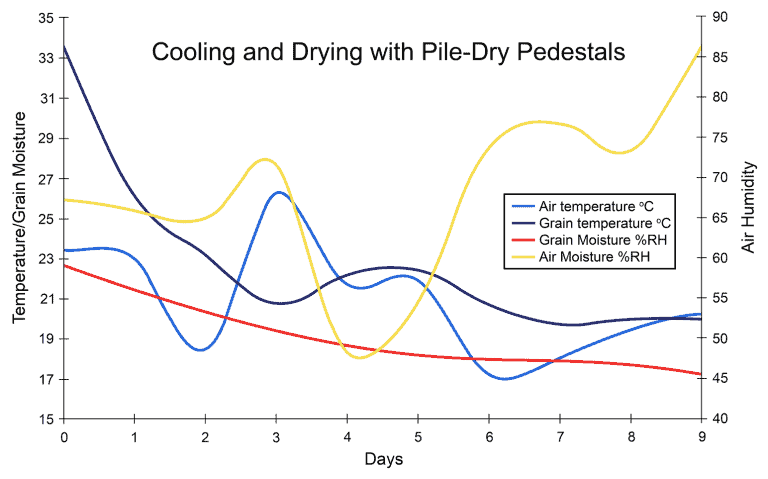

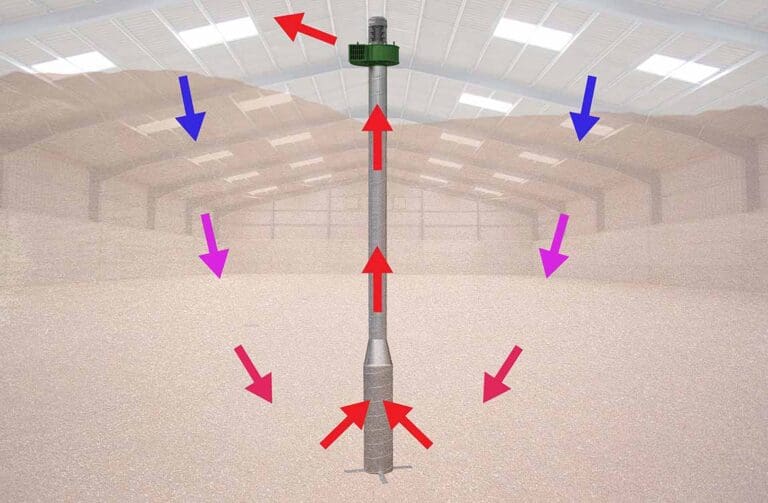

Martin Lishman Pile-Dry Pedestals continue to be the fastest most efficient vertical crop cooling system on the market, operating at 20% above the required rate. Pile-Dry Pedestals will cool grain straight off the combine and chill the grain to avoid insects and harmful moulds.

Fans suck cool air through the stored crop and extract the warm air out of the heap to achieve safe storage conditions. The Pile-Dry Pedestal design is modular, meaning they can be placed in almost any existing grain store, even in grain at depths greater than 17 metres.

Powerful cooling

Martin Lishman Green Pile-Dry low volume grain cooling fans have become the ultimate in fast cooling performance. With highly efficient IE3 motors and uprated design to ensure long lasting reliability, when used in conjunction with Pile-Dry Pedestals farmers can cool crops faster and more energy efficiently while preserving crop quality in all sizes of store and all bulk stored crops.

To get the best cooling results from Pile-Dry Pedestals and Fans, Martin Lishman offers 4 key tips for success:

- Use at least one fan per 4 Pedestals

- Increase this quantity for faster cooling

- Move the fans between Pedestals as the crop cools

- Use Automatic Fan Control to save energy and achieve the fastest cooling

“One of the simplest ways to improve the effectiveness of a pedestal cooling system is to use more fans,” explains Gavin Lishman, Managing Director of Martin Lishman Ltd. “It is not uncommon to swap fans between pedestals when required, but this slows down the cooling process and requires more frequent temperature checks. Using one fan per pedestal ensures the cooling power is instantly available when needed and significantly reduces the possibility of hot spots in the grain or forgetting to move fans around.”

Regular grain temperature monitoring

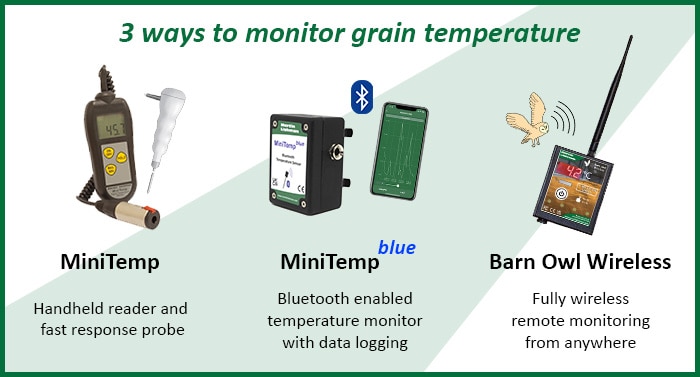

With higher-than-normal temperatures expected, frequently monitoring the grain to ensure the temperature is consistent throughout the store is crucial to preventing any form of deterioration. Martin Lishman offers systems to monitor stored grain that cater for a range of budgets, including the well trusted MiniTemp hand-held temperature monitor, its new Bluetooth brother, MiniTemp Blue, and Barn Owl Wireless, the fully automatic wireless monitoring and automatic fan control system.

Automatic fan control

An automatic fan controller can bring with it many benefits. Automatically turning cooling fans on and off to make the best use of ambient air conditions ensures the fastest cooling possible but can also save at least 40% of energy costs. Plus, there is the bonus of reducing trips to the store to manually operate fans, or simply avoiding forgetting to do so.

Hot spot spears

With spikes in ambient temperatures, hot-spots in grain can take you by surprise and can wreak havoc in the store if not dealt with quickly. Martin Lishman screw-in Trouble-Dry aeration spears tackle hot spots by simply screwing the spear into the heap and using one of their high output green fans to suck cool air out of the affected area. They are ideal for cooling small quantities of grain, urgent spot drying and controlling unexpected insect infestations.

Don’t forget about quality control!

The challenge of achieving the highest quality grain relies on more than just good ventilation. Making sure the store is fit for purpose and carrying out regular assessments can help identify problems before it’s too late. Martin Lishman supplies a range of crop quality equipment such as insect traps to detect the presence of insects, sampling spears to cater for crop moisture testing or lorry load profile sampling, ambient air measurement devices and accurate moisture meters such as the Protimeter Grainmaster.

The Martin Lishman team are standing by for advice on optimising your crop store ready for harvest! For more information on Martin Lishman’s crop storage equipment, visit www.martinlishman.com.