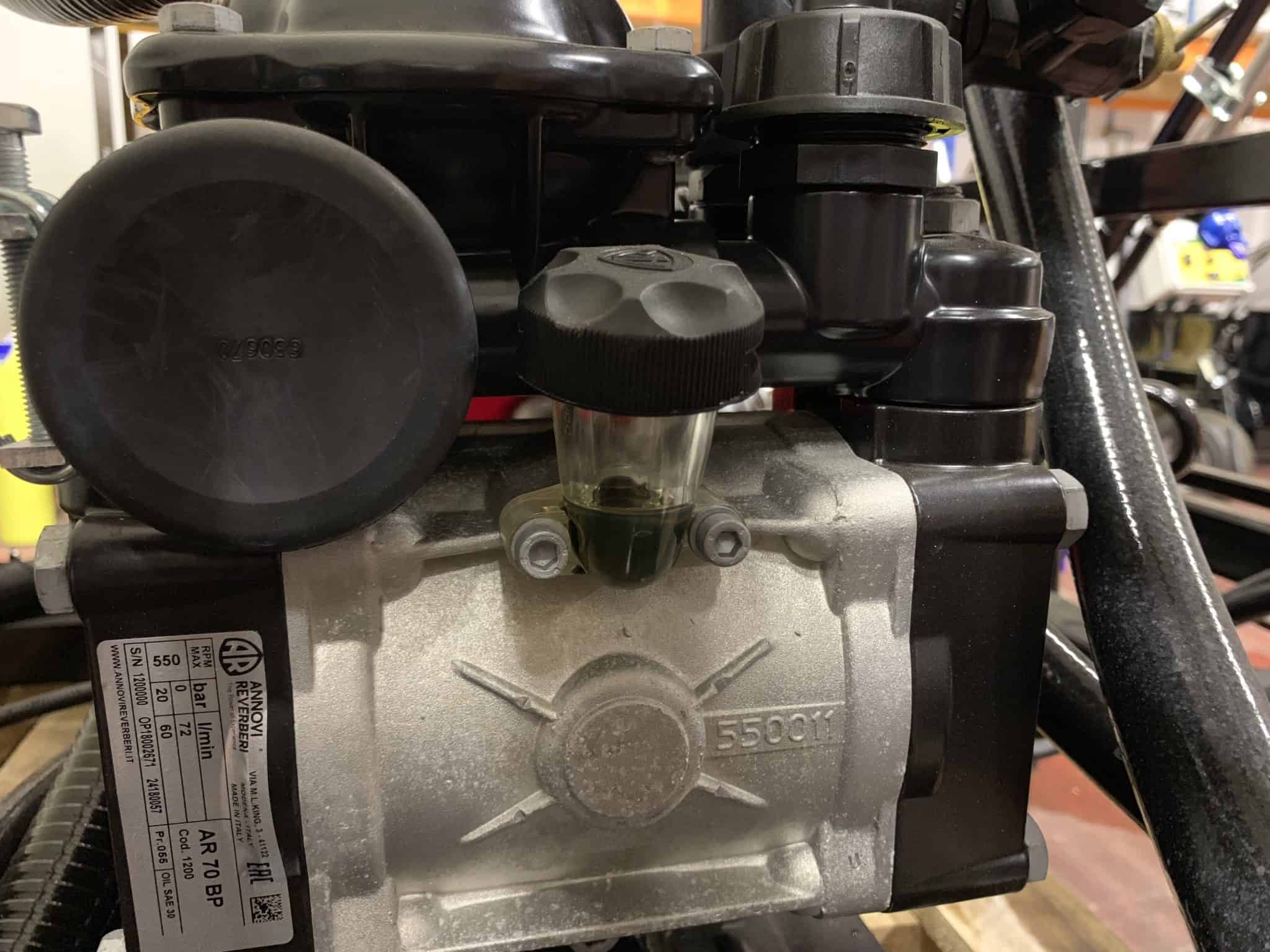

The Pump

This is the heart of the sprayer; a failing pump can lead to a lack of pressure and performance. Here are a few things to look for:

1. External leaks: This is usually a sign of faulty diaphragm(s), cracks, loose components or fittings.

2. Loss of pressure: This can be the result of Diaphragms or sealing components of pumping elements or foreign material in valves (check filter). Is the pump rotating at the correct speed? (Check electric supply is suitable and working properly for electric pump, and check the PTO speed is correct on output of tractor for engine driven pumps)

3. Vibration on pressure side: This can point to an air leak on the suction side of the pump (or pipe work) or faulty valves.