As potatoes come into store, the job isn’t over. Small details now make the biggest difference to quality, marketable yield, and shelf-life.

Here’s a simple checklist to help ensure your crop stays in top condition throughout storage:

1. Check Dry Matter and Bruising Risk

Understanding dry matter levels gives a good indication of how your crop will behave in storage and how susceptible it may be to bruising.

Our range of Dry Matter testers provide fast, reliable readings so you can make informed decisions from day one.

To assess bruising risk quickly, the Martin Lishman Potato Hot Box accelerates the bruising detection process to just 12 hours. This allows you to identify issues early and adjust handling or storage conditions before quality is affected.

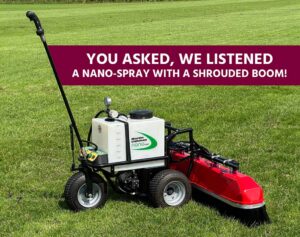

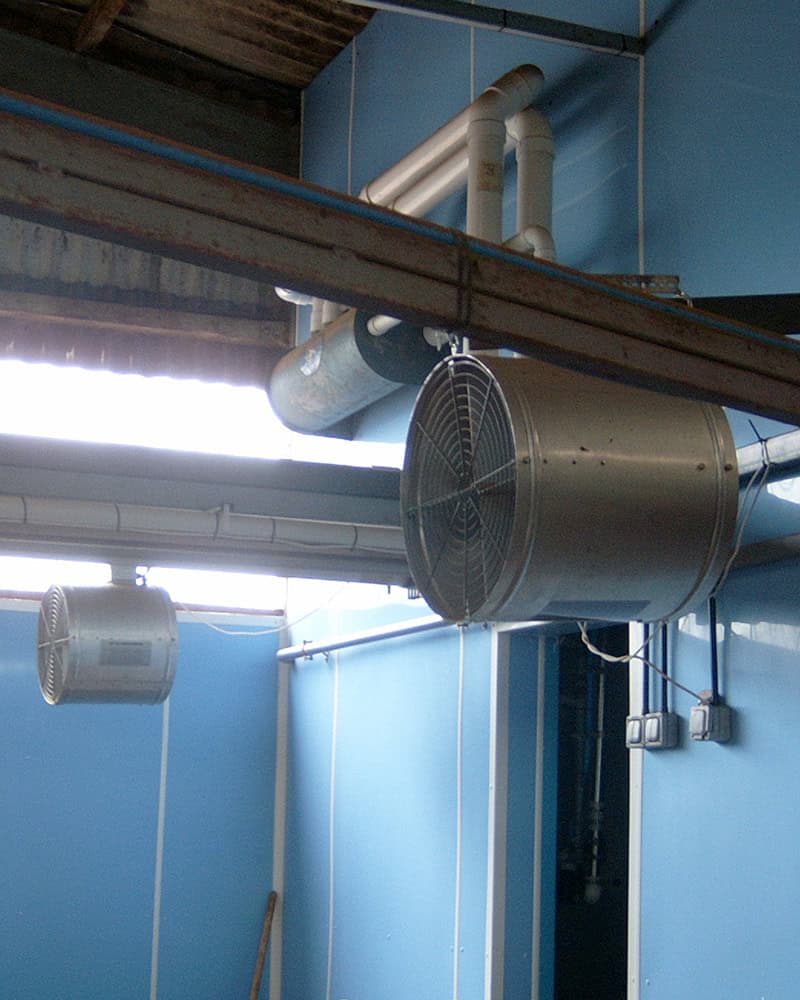

2. Ensure adequate ventilation

A clean, well-ventilated store helps reduce disease pressure and maintain quality.

Depending on your storage setup, maintaining a consistent and controlled airflow is vital to keeping potatoes in good condition. Martin Lishman supplies a wide range of building ventilation systems designed for both box and bulk stores, from simple extraction fans to fully integrated air movement solutions.

And with the option of automatic fan control, your ventilation only runs when conditions are right, improving efficiency, protecting quality, and avoiding unnecessary energy use.

3. Keep a Close Eye on Temperature, Humidity & CO₂

Consistent store conditions are essential for maintaining potato quality. Monitoring conditions is essential. Rising CO₂ levels can signal increased respiration or early disease activity, while inconsistent temperatures and humidity can cause condensation and uneven crop quality. Keeping these factors stable is key to protecting your potatoes in store.

We offer monitoring solutions for every scale of store, from simple hand-held thermometers and probes to Barn Owl Wireless, which provides real-time temperature, humidity, and CO₂ monitoring, with the option for automated fan control.

This means you see exactly what’s happening in your store at any time, and your fans operate only when conditions are right — protecting crop quality while reducing energy use.

4. Record Keeping

Good record keeping is one of the most overlooked aspects of potato storage. Keeping track of store conditions, energy use, and management changes not only helps you understand how your store is performing, but also allows you to demonstrate improvements over time.

Barn Owl Wireless is ideal for this. The system automatically records temperature, humidity, CO₂ levels and fan run hours over the entire storage period. It can even calculate fan energy usage, giving you a clear picture of storage costs and showing where efficiencies can be made.

Over a season, these records build valuable insight, helping you reduce energy use, improve consistency, and protect crop quality.

5. Regular In-Store Checks

Even with good monitoring in place, nothing replaces a physical check. A single rotten potato can quickly spread soft rot and spoil surrounding tubers if left unnoticed. Make it part of your routine to inspect the store at least once a month, and more frequently in the early storage period.

Look for signs of rot, condensation or heating pockets, and remove any affected potatoes along with those directly in contact to prevent further spread. A few minutes of inspection can protect a lot of value in the long run.