Managing post-harvest grain storage efficiently has always been a challenge for farmers, especially with rising energy costs and increasing concerns over crop quality. For Sutton Cheney Farms Partnership, a 2,000-acre family-run estate in Warwickshire, ensuring their new 3,200-ton grain store operated at peak efficiency was a top priority. Their solution? Martin Lishman’s Barn Owl Wireless and FloorVent systems, which have completely transformed their storage process.

“We needed a system that could effectively draw heat out of the crop while avoiding issues like condensation or poor air circulation,” explains Tom Ingram, Farm Manager at Sutton Cheney Farms. “We feel that traditional ventilation floors can blow warm air back into the shed, which isn’t ideal for keeping the grain in top condition. With FloorVent, the warm air is extracted directly outside, ensuring better conditioning of the stored grain.”

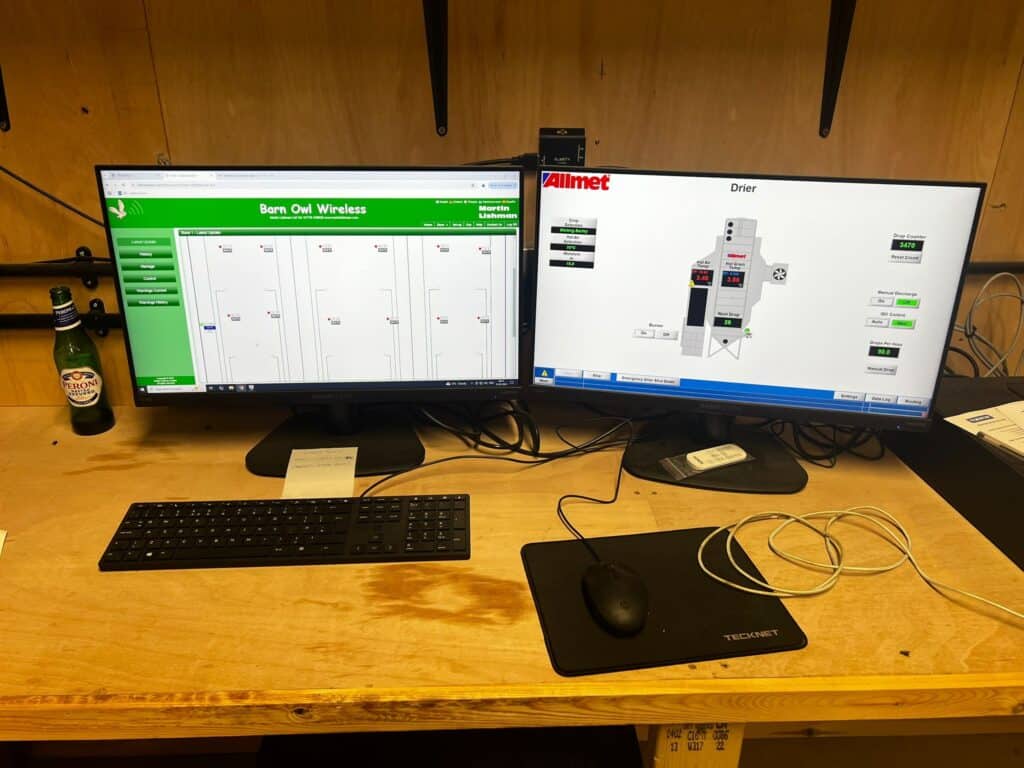

Tom and the estate owners also sought a monitoring system that would allow them to keep track of storage conditions without having to manually check crop temperatures. “We opted for Barn Owl Wireless because it offers both monitoring and fan control automation,” he says. “It also improves health and safety – there’s no need to walk across the grain, reducing the risk of accidents. Once the sensors are in, we can track temperatures remotely without stepping foot inside the store.”

The impact of the system was immediate. Crop temperatures dropped from an average of 22°C in August to 12°C in September – exactly the result the team was hoping for. “FloorVent did a fantastic job of pulling the heat out, cooling the crop quickly and effectively. Now, with Barn Owl Wireless, we can check temperatures immediately using the web app, whether we’re in the control room or out in the field.”

For Sutton Cheney Farms, choosing Martin Lishman was an easy decision. “We had already been using Martin Lishman’s products, like the Trouble-Dry hot spot spears and Pile-Dry Pedestals, and their service has always been excellent,” says Ingram. “When we built the new grain store, it made sense to continue working with a company we trusted. Jordan from Martin Lishman was brilliant during the commissioning process – everything was set up smoothly, and we were up and running in no time.”

The results speak for themselves. “The crop has been well-conditioned and stored safely. We’ve had no issues with moisture or temperature affecting grain quality, and we’ve had no rejections from buyers,” Ingram confirms. “For any farm looking to improve their storage setup, I’d highly recommend this system.”

By integrating Martin Lishman’s FloorVent and Barn Owl Wireless systems, Sutton Cheney Farms has optimised grain storage, improved efficiency, and reduced labour costs—proving that smart storage solutions are key to successful post-harvest management.